In the rapidly advancing field of manufacturing and quality control, vision inspection has emerged as a critical tool for ensuring accuracy, efficiency, and reliability. This technology leverages sophisticated imaging systems to analyze and inspect various processes, materials, and products. In this article, we will delve into the fundamentals of vision inspection, its various applications, and the benefits it brings to industrial operations.

What is vision inspection?

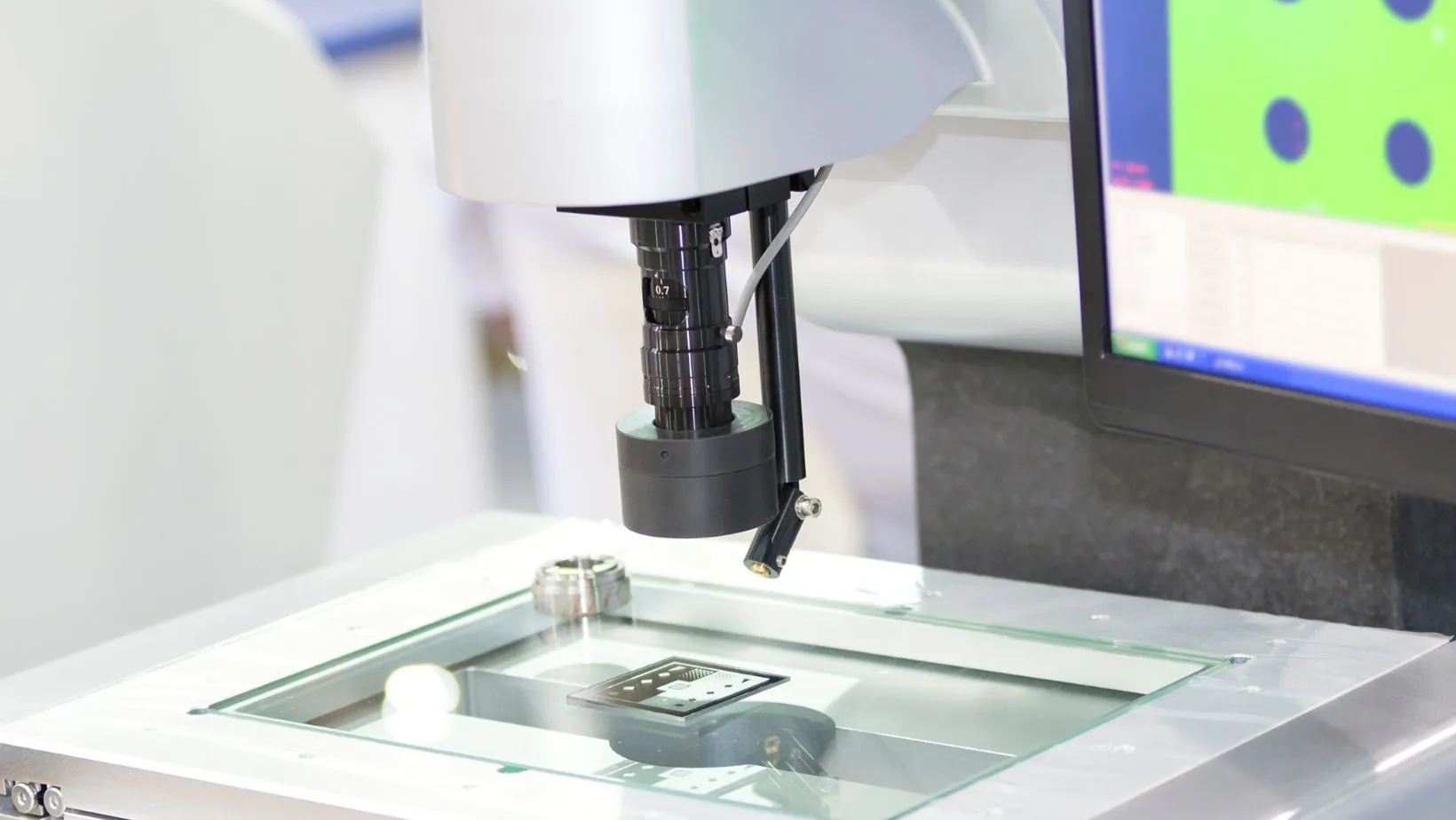

Vision inspection is a technology-driven process that uses cameras and image processing software to evaluate the quality of products, components, and assemblies. It is a subset of machine vision, which encompasses the broader use of image technology in machinery. Vision inspection systems are designed to detect defects, measure dimensions, identify patterns, and perform complex tasks with high precision, all at incredible speeds that far surpass human capabilities.

Key components of vision inspection systems

Vision inspection systems consist of several critical components, including:

- Camera: Captures images of the product or component being inspected.

- Lighting: Illuminates the object to enhance image clarity and highlight features.

- Processor: Analyzes images using various algorithms to detect defects or anomalies.

- Output device: Communicates results, often through a display or automated action.

Types of vision inspection systems

Vision inspection systems can be categorized into several types based on their applications:

- 2D Vision Inspection: Utilizes flat images for surface inspections, such as label verification or cosmetic inspections.

- 3D Vision Inspection: Involves capturing objects in three dimensions for depth and volumetric analysis crucial in complex assembly verifications.

- Line Scan Systems: Ideal for inspecting continuous materials such as textiles or coatings.

Applications of vision inspection

Vision inspection technology has a wide range of applications across various industries.

Here are some notable examples:

- Automotive: Ensures the quality and accuracy of parts, from engine components to body panels, reducing recall risks and improving safety.

- Food and Beverage: Inspects packaging integrity, labels, and product defects, ensuring compliance with regulations and consumer safety.

- Pharmaceuticals: Conducts inspections for packaging errors, label validation, and tablet defects, maintaining product quality and adhering to stringent regulatory standards.

Benefits of adopting vision inspection

The integration of vision inspection systems into manufacturing and production processes offers numerous advantages, including:

- Increased Accuracy: Provides unparalleled precision in defect detection, significantly reducing the occurrence of errors.

- Enhanced Efficiency: Speeds up inspection processes, allowing for quick identification and correction of issues without halting production.

- Cost Reduction: Minimizes waste, reduces labor costs, and prevents costly recalls due to defective products escaping into the market.

Challenges in vision inspection

Despite its many benefits, vision inspection systems also face certain challenges:

- Complex Setup: Systems require precise calibration and alignment to function correctly, potentially leading to implementation difficulties.

- Environmental Factors: Variations in lighting, temperature, and movement can affect system performance and require continuous adjustment.

- Maintenance Needs: Regular maintenance and updates are necessary to ensure optimal performance and to keep up with evolving technology standards.

The future of vision inspection

As technology continues to evolve, vision inspection systems are expected to become even more sophisticated and accessible. The integration of artificial intelligence and machine learning will likely propel vision inspection to new heights, making systems smarter and more adaptable to dynamic production environments. Industries across the globe will increasingly rely on these technologies to maintain competitiveness and ensure the highest quality standards.

In conclusion, vision inspection is a powerful tool transforming the landscape of quality control and manufacturing. By understanding its components, applications, benefits, challenges, and future potential, companies can harness its capabilities to drive efficiency, accuracy, and cost-effectiveness in their operations.