Choosing the correct sheet metal fabrication provider for your project is an important decision that should be carefully considered. By evaluating the supplier’s capabilities, quality standards, lead times, customer service, and track record, you may identify a partner who will provide high-quality components on time and within budget. Obtaining a precise sheet metal estimate is an important stage in this process since it helps you to compare suppliers and make informed decisions. With the correct provider, you can ensure that your project succeeds and achieves the intended results.

The Evolution of Custom Metal Fabrication

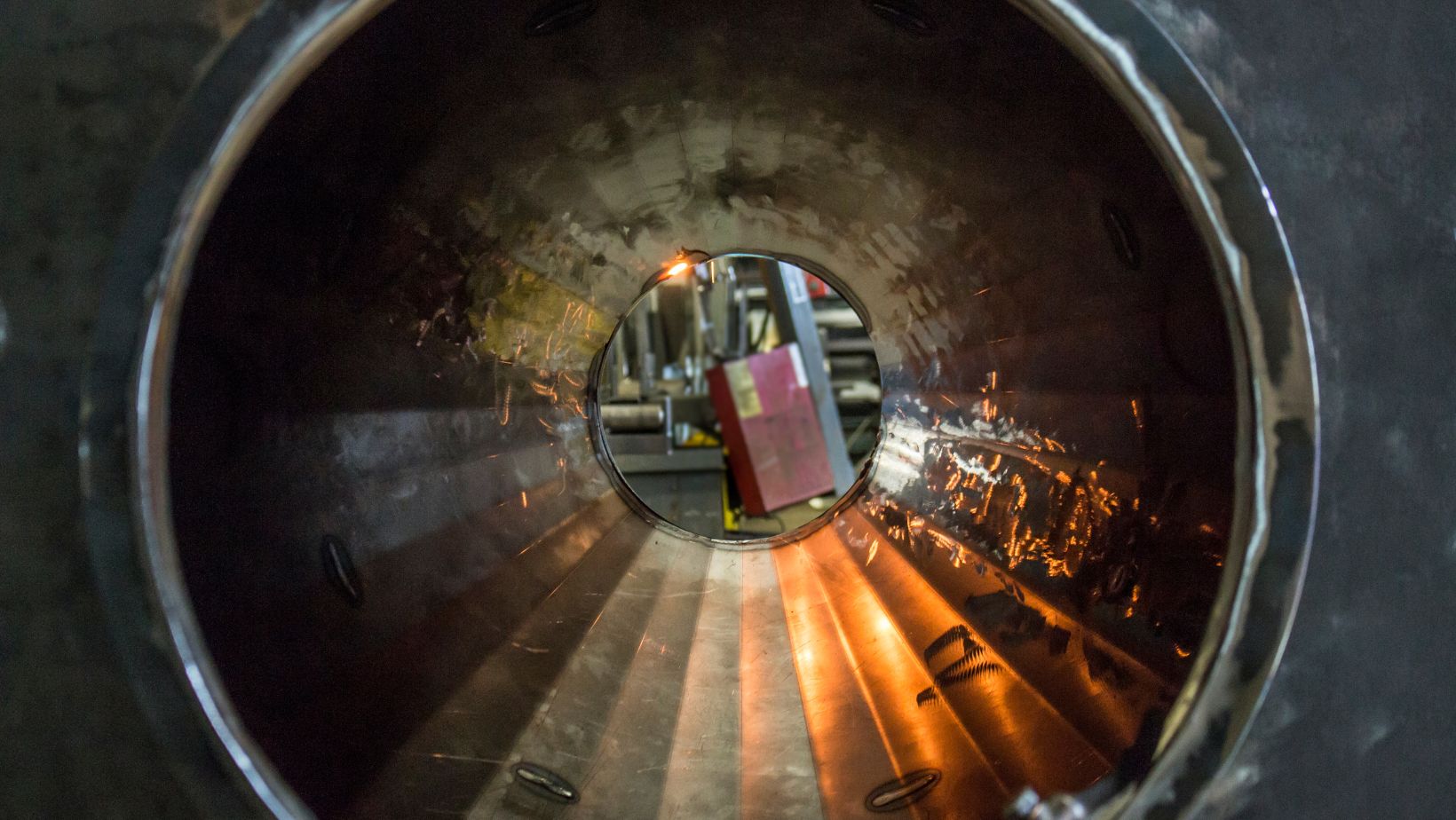

Custom metal fabrication has long been at the heart of production, allowing for the creation of customized components that meet exact specifications. Previously, this procedure entailed a tight collaboration with metal fabrication firms, which frequently necessitated precise designs, in-person consultations, and multiple revisions before reaching the final product. The procedure could take weeks or months, depending on the design’s complexity and material availability.

Today, the rise of online metal fabrication platforms has shortened this process, allowing firms to attain the same level of personalization while being more efficient and cost-effective. These platforms ease the customization process by utilizing advanced technologies like as computer-aided design (CAD) software, automation, and real-time pricing. As a result, firms can now design, develop, and order unique metal parts in days, not weeks.

The Power of Online Customization Tools

One of the most significant advantages of online metal fabrication platforms is the ability to easily personalize parts. These platforms often include simple design tools that enable users to construct detailed 3D models of their desired components. Users can enter their parameters, such as measurements, material type, and finish, directly into the platform, which will generate a visual depiction of the part.

These design tools frequently include a variety of modification choices, allowing users to fine-tune every part of their design. For example, a company may require a special form of bracket with unique hole placements, a specific thickness, or an unusual material. They can make these alterations in real-time real time using online tools, and the changes will be reflected in the 3D model right away. This level of control ensures that the final result fulfills the project’s exact specifications.

Streamlined Communication and Collaboration

In traditional metal fabrication, communication between the client and the fabricator is critical, but it can also lead to irritation and delays. Miscommunications or misunderstandings of design specifications might result in costly errors and changes. Online metal production systems address this issue by giving clear, visual representations of the designs, which reduces the possibility of errors.

Furthermore, several of these tools enable easy collaboration. Teams can collaborate on a design, make real-time revisions, and provide feedback using the platform. This collaborative method not only accelerates the design process but also assures that all stakeholders agree before manufacturing begins.

Instant Quoting and Cost Transparency

One of the issues that firms experience when dealing with custom metal fabrication is a lack of cost transparency. Traditional techniques frequently necessitate many consultations to estimate the ultimate cost, which can vary greatly based on factors such as material availability, manpower, and manufacturing time.

Online metal fabrication systems provide quick pricing, allowing users to view the cost of their design as they make changes. This real-time cost input allows organizations to make informed design decisions while balancing personalization and budget constraints. By providing clear and open pricing, these systems assist firms in avoiding unforeseen costs and staying within budget.

Rapid Prototyping and Iteration

Prototyping is an important step in the product development process because it allows firms to test and perfect their concepts before moving them into full-scale production. However, traditional prototyping may be a time-consuming and costly procedure, especially when dealing with unique metal parts.

Online metal fabrication platforms have made quick prototyping more convenient and inexpensive. Users can easily construct prototypes of their concepts, have them delivered within days, and make any necessary changes. This rapid prototype approach enables faster iteration and shortens the time to market for new goods. Businesses can experiment with various ideas, materials, and finishes without committing to huge production runs, resulting in improved end goods.

Access to a Wide Range of Materials and Finishes

Customization entails not only the design but also the selection of the appropriate materials and finishes to satisfy the project’s individual requirements. Online metal fabrication platforms often provide different a diverse selection of sheet metal, ranging from conventional metals like steel and aluminum to more specialty possibilities such as titanium and copper alloys. Users can also select from a variety of treatments, including powder coating, anodizing, and polishing, to get the appropriate aesthetic and functional features.

These platforms frequently give thorough information on each material and finish, allowing users to make informed judgments based on properties like as strength, corrosion resistance, and cost. This level of choice allows organizations to choose the best materials and finishes for their specific application, resulting in a finished product that meets both performance and visual standards.

Seamless Integration with Manufacturing Processes

Another advantage of online metal fabrication platforms is their ability to connect smoothly tointo existing manufacturing processes. When a design is complete, the platform may automatically produce the appropriate files and instructions for fabrication. This automation decreases the possibility of errors in production and assures that the finished product meets the original design parameters.

For enterprises that require large-scale production, online metal fabrication platforms can easily manage bulk orders. The ability to manufacture several units of consistent quality is a huge benefit, especially in industries that require accuracy and reproducibility.

The Future of Custom Metal Fabrication

As technology advances, the potential of online metal production platforms will only increase. We should expect more complex design tools, expanded material options, and deeper interaction with other manufacturing technologies such as 3D printing and CNC machining. Furthermore, the advancement of artificial intelligence (AI) and machine learning may result in smarter platforms that can provide design refinements, further easing the customization process.

For organizations, the change to online metal fabrication represents a chance to improve manufacturing capabilities, cut costs, and get goods to market more quickly. The ease of customization provided by these platforms enables businesses of all sizes to build bespoke metal parts without the usual hurdles of time, cost, and complexity.

Conclusion

The introduction of online metal fabrication tools changed the way businesses approached custom metal fabrication. By offering easy design tools, rapid quotation, and access to a diverse choice of materials and finishes, these platforms have made it easier than ever for businesses to design and purchase customized metal parts. As the industry evolves, online metal fabrication will become increasingly important in satisfying the rising demand for personalization in manufacturing.

Whether you’re a small business looking to prototype a new product or a major factory in need of precision components, online metal fabrication platforms provide the tools and capabilities you need to bring your designs to life with remarkable ease and speed. With the appropriate platform, custom metal fabrication is no longer a frightening task, but rather a streamlined process that enables firms to innovate and thrive in a competitive market.